Acmax Channel | Dual Compressor Safety Controller, ETCLO-830

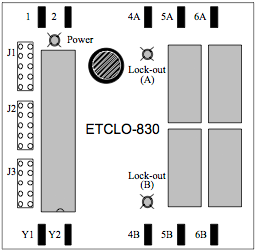

Dual Compressor Safety Controller, ETCLO-830

|

The ETCLO-830 Compressor Safety Controller has an anti-short cycle, solenoid valve time delay and lead-lag multi-settings. It is designed for use with any single and two-stage air conditioning and refrigeration equipment for compressor operation and protection control. If during normal operation any safeties are opened (low or high pressure switches), the compressor will shut off immediately. The controller then restarts the A/C unit again and a warning flag will be set. The compressor will be locked-out if safeties are opened for a second time. Manually opening and closing the thermostat can restart the A/C unit and reset the board. The fault can be attended to at any convenient time. The early warning feature will save the compressor from burnout. |

During normal operation of the compressor, contacts 5 and 6 will be energized, as well as the safety contacts that are in series with contact 6 and the compressor’s contactor. In this state, the warning flag (in the processor’s memory) will remain reset and normal operation will continue. If during normal operation safety contact(s) opens, the warning flag will be set and the compressor will shut off immediately. Terminals 5 and 6 will open for the duration of the selected anti-short cycle time delay (ASTD). Upon completion of this delay, contact 5, followed by 6, will re-energize. At this time there are two possible outcomes to this scenario: A - If the safety contact(s) is still open, the board will immediately go into lock-out mode, so that contacts 5 and 6 will be opened and the TRIAC output at terminal 4 (alarm output) will be activated. OR B - If the safety contact(s) is now closed, the compressor will start running again. However, the warning flag will remain set. If a safety contact(s) opens, the related compressor will immediately go into lock-out mode. Under condition B, the warning flag will be reset after 30 minutes of successful running of the compressor. In test mode, the 30 minutes for warning flag will be reduced to 4 seconds. When the thermostat is satisfied, the warning flag will be reset. The board is equipped with one green LED that indicates power to the board. Two red LEDs indicate the lock-out condition for each compressor. After power interruption, a unique time delay of 0–60 seconds for random start begins to avoid simultaneous start of multi-unit applications.

Terminal Designation

Jumper Settings Three sets of five position jumpers (J1, J2 & J3) are used to select functions as per tables below. Only one shunt should be applied to each jumper (except J3 in test mode).

The ETCLO-830 is designed for class 2 circuits and should be powered by an UL recognized class 2 24 VAC transformer. |

|

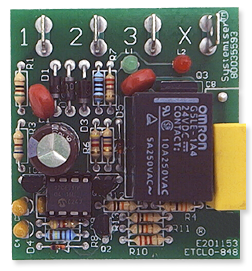

Single Compressor Safety Controller, ETCLO-848

|

The ETCLO-848 Compressor Safety Controller with fixed anti-short cycle delay is designed for use with any single stage air conditioning and refrigeration equipment as compressor protection. If during normal operation any safeties are opened (low or high pressure switches), the compressor will shut off immediately, and then the controller manages the restart of the A/C unit and a warning flag will be set. The compressor will lock-out if safeties are opened for a second time. Manually opening and closing the thermostat can restart the A/C unit and reset the board. The fault can be attended to at any convenient time. The early warning feature will save the compressor from burnout. |

When the thermostat demands for cooling, terminal 3 will be energized. Assuming that all safeties (HP & LP) that are connected in series with terminal 3 are closed, the warning flag (in the processor memory) will remain reset and normal operation will continue. If during normal operation (thermostat contact closed) any safeties contact(s) opens, the warning flag will be set, the compressor will be shut off immediately and terminal 3 will open. This state will remain for the duration of the selected anti-short cycle delay. Upon completion of the anti-short cycle delay, terminal 3 will re-energize. At this time, the controller monitors the operation of the safeties and takes decision based on: A - If the safety contact(s) are still open, the board will immediately go into lock-out mode, so that terminal 3 will be opened, and the TRIAC output at terminal X will be activated (board will go into lock-out mode). OR B - If the safety contact(s) are now closed, the compressor will start running again. The warning flag will remain set. If safety contact(s) opens, the board will forfeit the anti short cycle delay and will immediately go into lock-out mode. The warning flag will be reset after a 1⁄2 hour (30 minutes) of successful continuous compressor running. Also, when the thermostat is satisfied, the warning flag will be reset. The board is equipped with two LEDs. The green LED indicates power to the board. The red LED indicates the lock-out condition. |

|

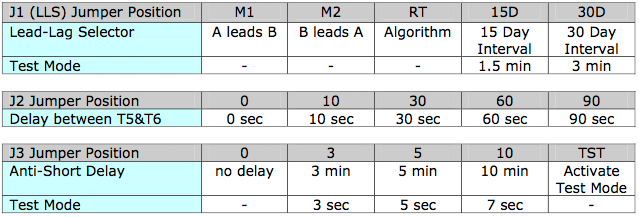

Dual Compressor Safety Controller, ETCLO-832

|

The ETCLO-832 Compressor Safety Control has an anti-short cycle, pump down solenoid valve time delay and lead lag multi settings. It is designed for use with any single and two-stage air conditioning and refrigeration equipment for compressor operation and protection control. If during normal operation, any safeties are opened (low or high pressure switches), the compressor will shut off immediately. The controller then restarts the A/C unit again and a warning flag will be set. The compressor will be lockout if safeties opened for second time. The A/C unit can be restarted manually by opening and closing the thermostat contact, which reset the board. The fault can be attended to at any convenient time. The early warning feature will save the compressor from burn out. |

The ETCLO-832 is provided with full size Snap Track for easy installation.

|

|

Economizer Controller ET-792 & ET-793 - Psychrotroll

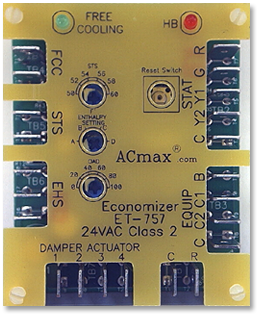

Economizer controller ET-757

|

One of the challenges that HVAC design engineers face is developing an air conditioning distribution system to deliver outdoor air to the occupants of a building. This task involves determining whether the outdoor air is acceptable for a free cooling system, and then developing an air intake and mixing control system that will deliver the needed amount of outdoor air to the building at an acceptable cost. This challenge can easily be met with the Economizer Controller ET-757. This controller allows a cooling air handler to supply outdoor air instead of re-circulated air in order to reduce or eliminate the need for a mechanical cooling system during mild or cold weather. If the outdoor air is below the high enthalpy (humidity and temperature) point as set on the board, and based on an analog signal from the enthalpy sensor, the controller will lock-out the compressor (mechanical cooling) and modulate the return and outdoor air dampers to maintain the cooling set point. When the outdoor air enthalpy exceeds the high enthalpy set point, the outdoor air damper moves to the set minimum position for ventilation. The ET-757 meets the requirements of AINSI/ASHRAE/IESNA Standard 90.1-2001, “Energy Standard for Buildings Except Low-Rise Buildings”. Energy saving and improved air quality make the ET-757 attractive to HVAC design engineers and building owners, not to the mention the fact that a system with such a controller usually pays for itself within one or two years. |

|

|

Economizer controller ET-858

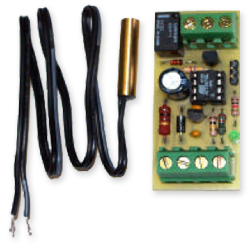

Temperature Controller, E610

|

The E-610 may be used as a simple temperature controller, providing on/off relay output for fans, heaters, shut off valves and alarm systems. Because of its software adjustable parameters, the product is highly customizable - an ideal solution for many OEM temperature control applications. |

The E-610 is a temperature controller with the ability to act as an ON/OFF temperature thermostat.The device is capable of fully stand alone operation. The unit may be programmed(preset in the factory) in one of three control modes: (a) temperature range mode in which it will turn ON the output relay between two defined temperatures (b) set point mode for heating mode iin which it will turn ON below adefined temperature and OFF above a defined temperature (c) set point mode for coolingmode in which it will turn ON above adefined temperature and OFF below a defined temperature |

|

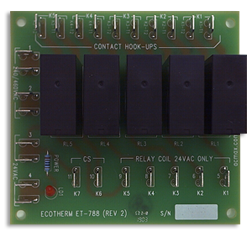

Power switching relay board (24 VAC, 5 RELAYS), ET-788

|

The ET-788 relay board is designed to convert 24VAC control signals to 240VAC dry contacts to operate 3-speed fans, compressors, heater relays, and other line voltage devices. |

|

|

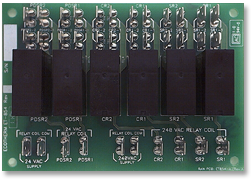

Power switching relay board (24 VAC, 5 RELAYS), ET-854

|

The ET-854 relay board is designed to convert 24 and 240VAC control signals to 240VAC dry contacts to operate 3-speed fans, compressors, heater relays, and other line voltage devices. |

|

|

Disc thermostat: Type EKB

|

Series EKB: 3⁄4” Disc Thermostat The sealed design of EKB provides moisture resistance for high humidity environments. Automatic reset for high and low temperature applications and manual reset for high limit temperature. The switch opens or closes its electric contacts on temperature rise. Surface and tube mounting options with a wide variety of terminals, lead wires and mounting options provide excellent design flexibility. Used in refrigerators, air conditioners, Ice makers freezers, as well as defrost termination and fan delay control. Temperature range: -30C to 80C (-22F to 176F) |

|

|

|

Disc thermostat: Type EKA

|

Series EKA: ½” Disc Thermostat EKA series is a compact design, auto and manual thermostat for controlling or limiting temperature changes. The switch mechanism is actuated by a snap-action bimetal disc, which opens and closes a set of electrical contacts when predetermined temperature is reached. The bimetal disc is electrically and thermally isolated from the switch. Different mounting configurations are available for maximum design flexibility: surface mount, air-stream and duct mounts. Used in boilers, heaters, vacuum cleaners, stoves, dryers, dishwashers and air conditioners. Temperature range: -30C to 170C (-22F to 338F) |

|

|

|

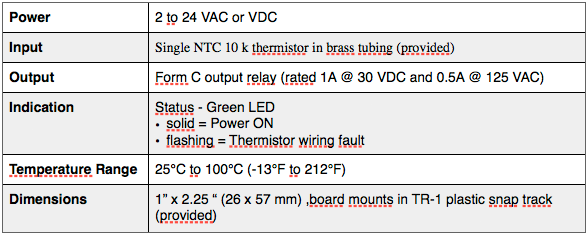

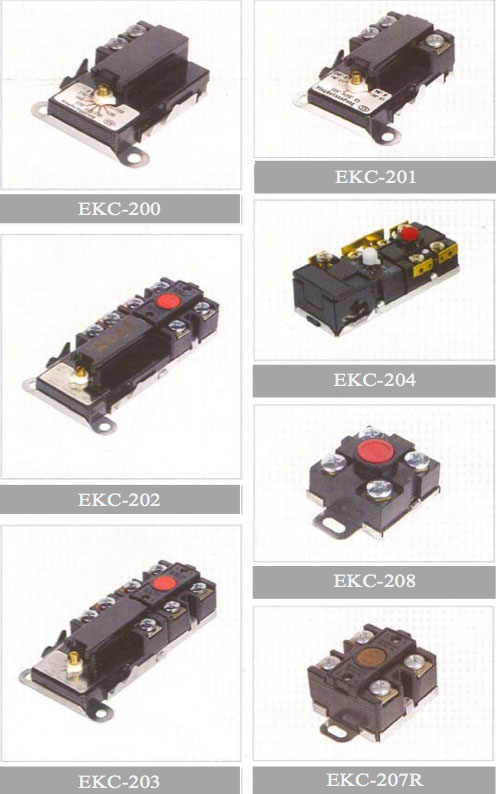

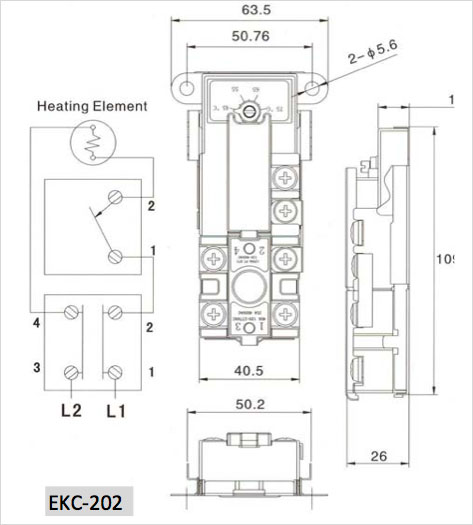

Disc thermostat: Type EKC

|

Series EKC: 3⁄4” Disc Thermostat (High Temperature) EKC is designed for heavy electric load, with a variety mounting flanges and terminal configurations. The snap action of the bimetal disc provides high speed contact separation ensuring long contact life cycle and eliminating contact chattering. EKC-0200 series is a narrow differential, adjustable temperature controls for applications where field adjustment is required such as electric water heaters. Widely used in HVACR equipment, vending machines, dryer and heaters. Temperature range: -30 to 170C (-22F to 338F) |

|

|

|

EKC-200

|

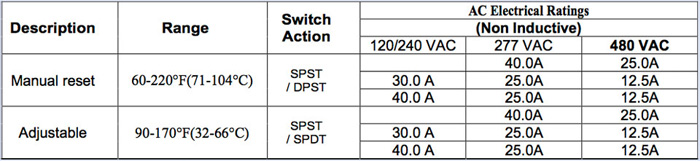

Electric Water Heater Thermostats and Limits Surface Mount Temperature Sensing Controls |

|

|

EWK Series ( High Current Thermostat)

|

With a high current capability switch of SPST or SPDT. There is a narrow differential and a forced OFF function. This kind of thermostats can be used in direct current (DC) with inductive loads. WK-B and WK-C series with bottom outlet terminals are available. Thermostats with a fix operating temperature(without a shaft) for air conditioner defrosting are also availabe. Available temp, range: -35~+40°C Adjustable temp, range: Max.20°C Differential: Min.2°C |

|

Room air conditioners, Freezers, Automobile air conditioners. |

|

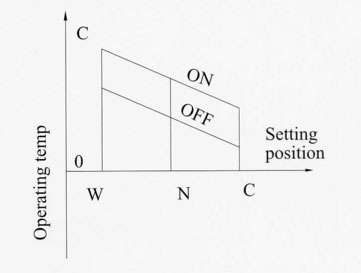

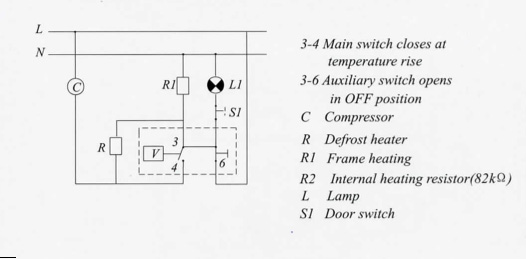

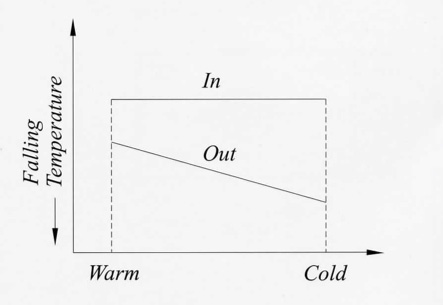

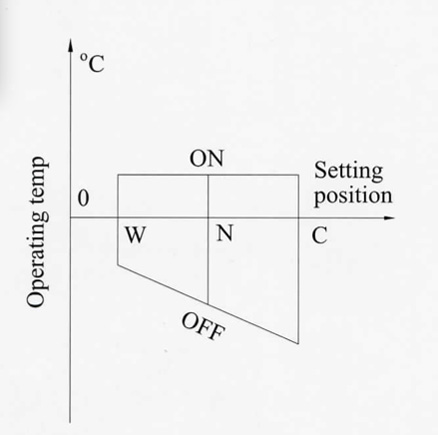

EWD Series ( Constant Cut-In Thermostat)

|

Terminal C-L cut-in at temperature rise. Terminal L-H of auxiliary switch cut-out when the shaft turned to OFF point. Terminal C-L can be cut-out at OFF point, and can be forced ON at ON point. The ON temperature is constant at any position from Warm to Cold, the OFF temperature is adjustable. This behavior assure an automatic defrost function. The WD-R series with an internal bellows heating resistance connected to C-L, is able to be used at cross-ambient in a refrigerator. Constant cut-in temp, range: +2~+8°C Available OFF temp, range: -36—4°C Adjustable temp, range: Max.l9°C Differential: Min.8°C |

|

Refrigerators. |

|

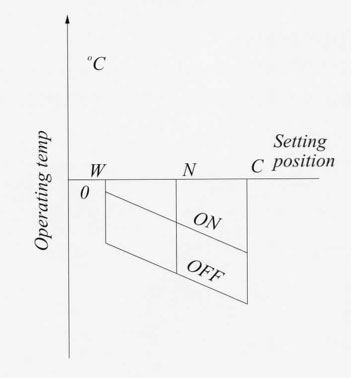

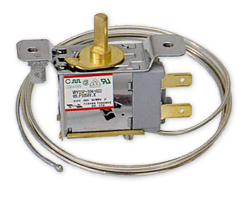

EWP Series ( General Purpose Thermostat)

|

Terminal C-L Cut-in at temperature rise. With SPST or SPOT, and an additional auxiliary switch. There are forced OFF and/or PD points. Type WP-T with two-spring mechanism is a wide differential range. Available temperature range: -36~+15°C Adjusting temperature range Max.25°C Differential: WP(5~14°C) 5-25 °C WP-T (10-25 °C) |

|

Refrigerating/freezing devices, Automobile air conditioeing |

|

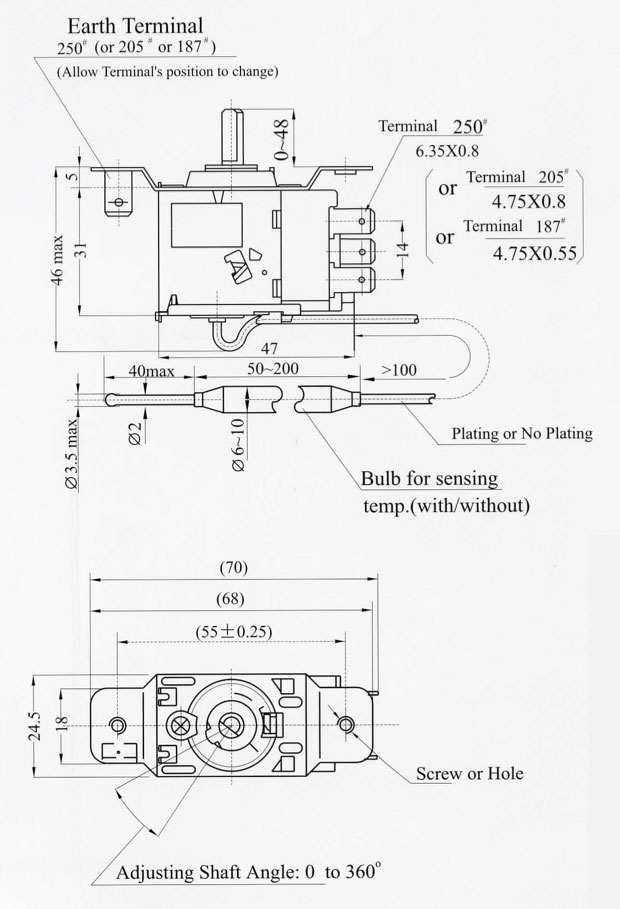

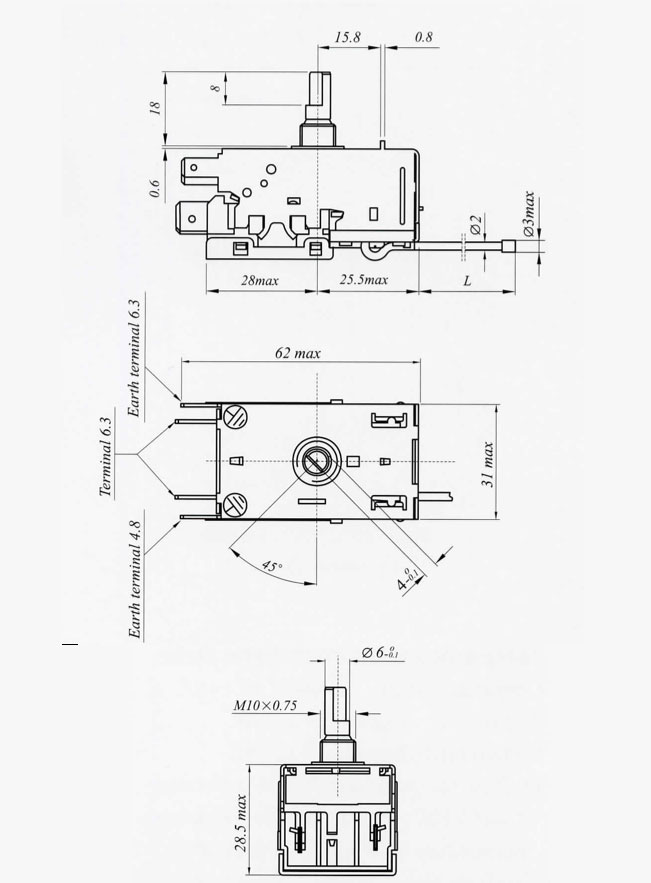

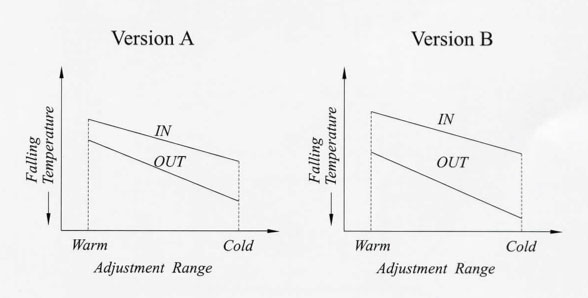

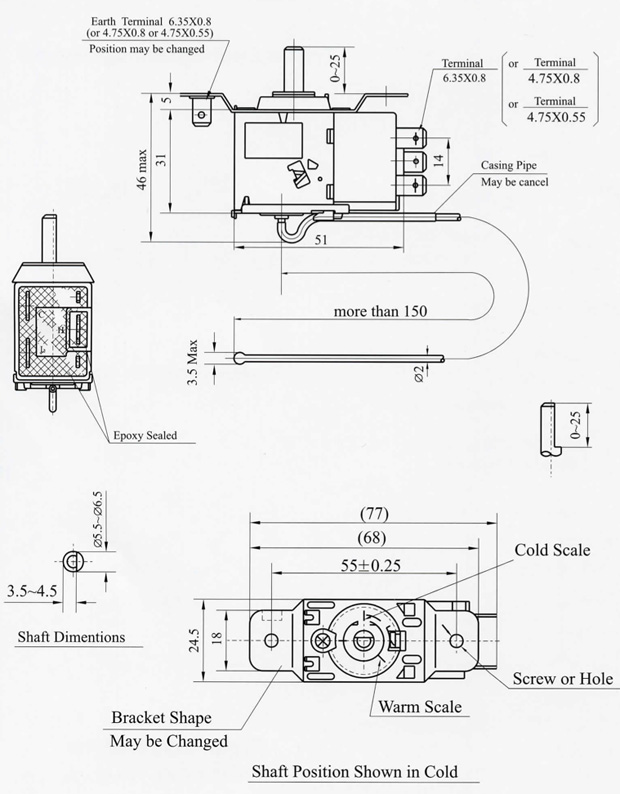

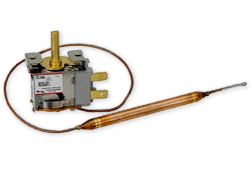

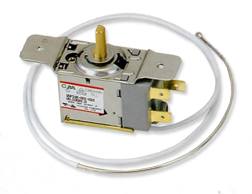

EKP Series (Temperature Control W/Coil Sensor)

|

Terminal 3-4 closes at temperature rise In general type KP is classified into 2 basic versions: Version A: KP with standard switching differential Version B: KP with wide switching differential Rating at 250 V 50 Hz 3-4: 6(6)A |

|

Operating range: -40 to+40°C Adjustment range: Vers ion A: 4 to 30K; Version B: 5 to 15K. Switching differential: Version A: 3 to 14K; Version B: 10to25K. Capillary type: Shape A (standard); Shape B (on request) Refrigerating/freezing devices Automotive air conditioning |

|

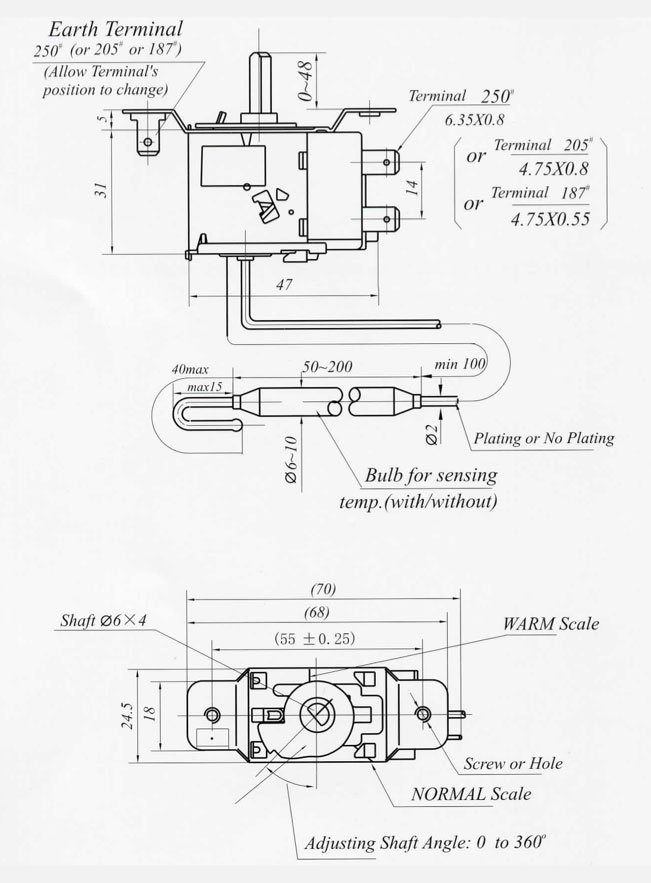

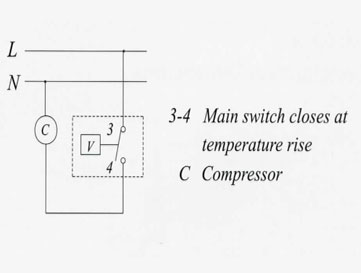

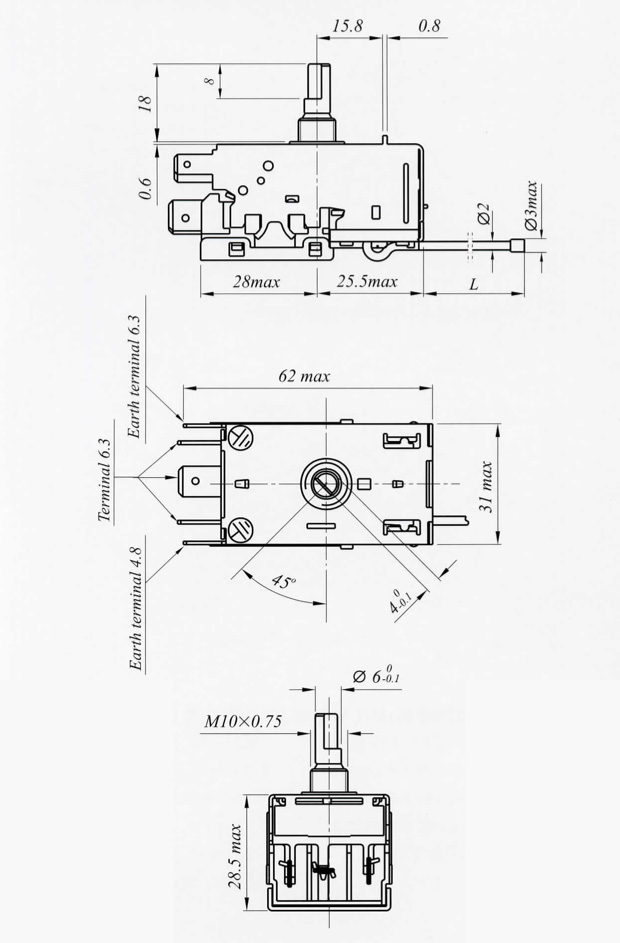

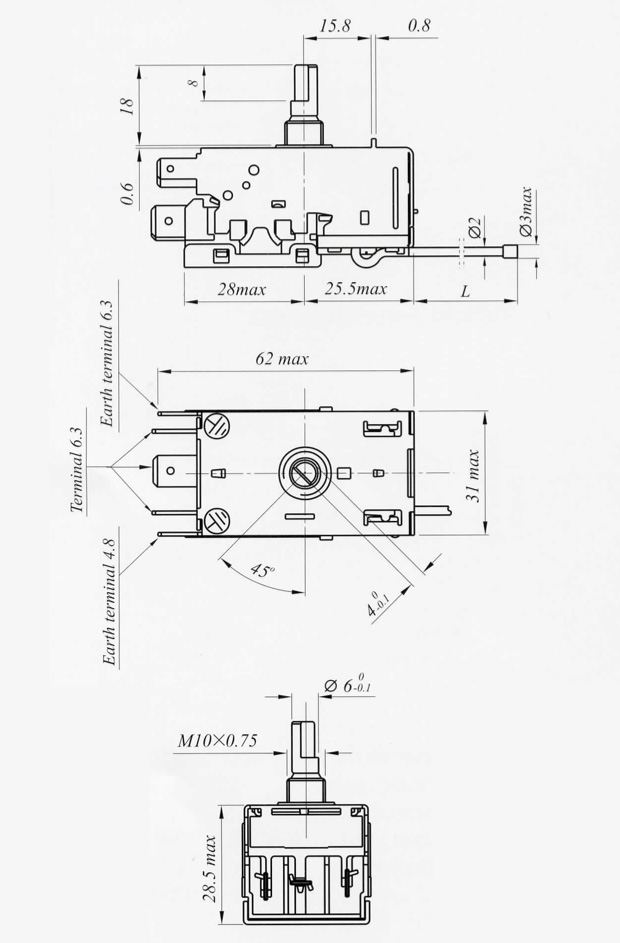

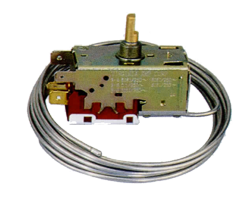

EKD Series (Thermostats w/auxiliary switch)

|

Temperature control with S.P.S.T. switchand auxiliary switch for off position. Automatic defrost function by constant cut-in value

Terminal 3-4 closes at temperature rise Terminal 3-6 opens in OFF position

Rating At 250 V 50 Hz 3-4: 6(6)A 3-6: 6(6)A |

|

Control shown in position COLD according to standard type, other dial shaft positions on request.

Operating range: -32 to +6°C Adjustment range: 4 to 18K. Constant cut-in value: +2 to +8K. Capillary type: Shape A (standard); Shape B (on request) Refrigerators |

|

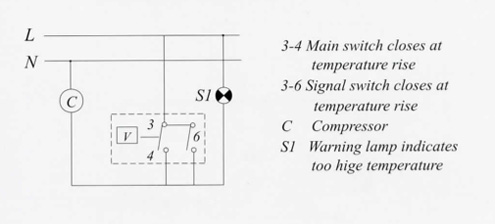

EKX Series (Thermostats w/alarm temp. switch)

|

Temperature control with S.P.S.T. switch and signal switch.

Terminal 3-4 closes at temperature rise Terminal 3-6 closes when warning temperature has been reached

Rating At 250 V 50 Hz 3-4: 6(6)A 3-6: 0.1A |

|

Control shown in position COLD according to standard type, other dial shaft positions on request.

Operating range: -40 to +40°C Adjustment range: 4 to 30K Switching differential: 3 to 14K Signal differential: 4 to 7K Capillary type: Shape A (standard); Shape B (on request) Freezers |

|

EWD-E Series (Thermostats for explosion area)

|

Constant cut-in thermostats for explosive area.

This is a special designed type with SPST switch plus an aux switch. It is an "n" type apparatus in accordance with the standard IEC79-15. It can prevent the possible explosion when the switch body is located in the explosive gas mixed air. Ex approval of China was obtained and VDE Ex test was past. Maybe with an internal bellows heating resistance connected to C-L terminal to enable to be used at cross ambient in a refrigerator.

|

|

Control shown in position COLD according to standard type, other dial shaft positions on request.

Constant cut-in temp, range: +2~+8°C Arailable OFF temp. Range: -36—4°C Adjustable temp, range: Max. 19°C Differential: Min. 6°C Refrigerators. |

|

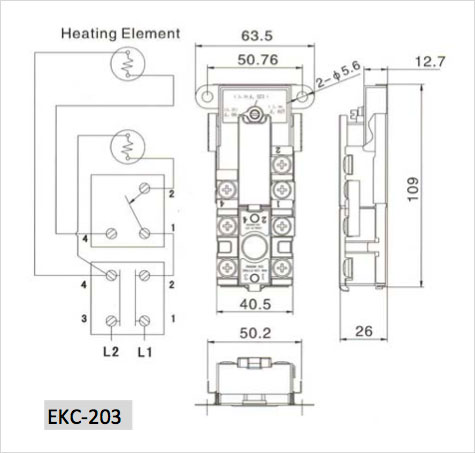

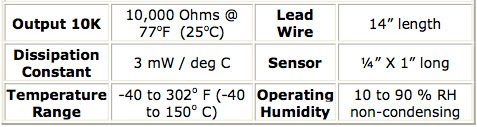

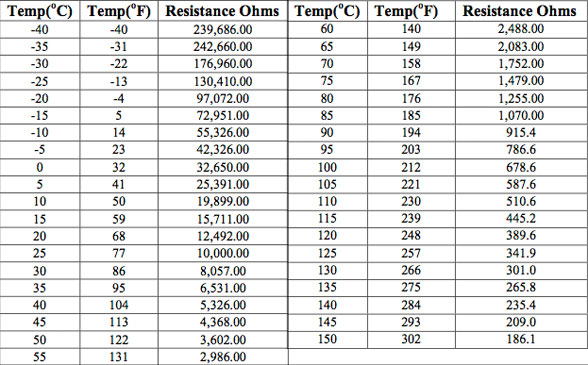

NTC Thermistor E-626

|

The E-626 is a NTC thermistor type sensor. This sensor provides a predictable output over a specified temperature range to meet user’s required input values. E-626 Thermistor offers high accuracy and interchange ability over a wide temperature range. |

|

|

|

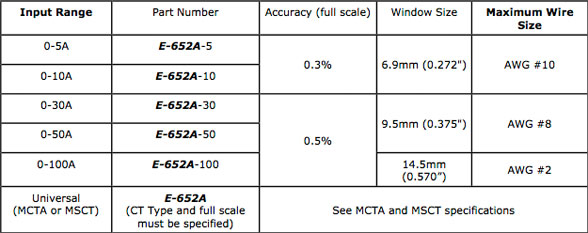

Current Transducer E-652A

|

The E-652A transducer offers inexpensive yet accurate true RMS monitoring of AC current in one circuit. This product is ideal as a precision AC load transducer for Control and Energy Management applications. Combined with a standard 5A CT the loop powered E-652A provides a convenient tool for accurate load monitoring in any electrical equipment. |

The E-652A is a precision current transducer that performs true RMS current measurements in one AC circuit wired through an interfacing CT mounted on the top of the enclosure. The E-652A may be ordered for various current ranges. The 0-5A and 0-10A current ranges feature a very high accuracy CT providing 0.3% accuracy (full scale). Other standard ranges include 30A, 50A and 100A. The 5A calibrated i-SnailÔ-A can be applied to the secondary wire of a 5A CT thus extending the metering range as required. The E-652A is powered from the 4 -20 mA current loop (it acts as a ‘two wire loop device’). It will accept a wide range of loop excitation voltages, typically 24 VDC. The unit is hermetically potted in a small plastic enclosure equipped with two mounting holes. A barrier strip terminal is provided for the output wiring. The E-652A does not include a built in CT and is equipped with spade connectors allowing remote installation of various Elkor miniature CTs (MCTA and MSCT).

|

|

Current Transducer E-652V

|

The E-652V offers an inexpensive means to monitor any electrical load. This product is ideal as an AC load transducer for Control and Energy Management applications. The built-in CT and self powered feature combine to make an easy to install, robust solution. |

The E-652V is a simple self power AC current transducer that provides a 0-5V analog signal proportional to the AC current flowing through the CT. Available in three ranges, the i-SnailÔ-V is calibrated to AC sine wave. There is no need for input current configuration nor trimming, saving time and confusion in the field. The transducer is enclosed in a fire retardant ABS box and encased in potting epoxy to withstand moisture, dust and vibration. The integrated mounting tabs provide an easy means to install the unit on a wall or within a control panel. The E-652V is ideal for load monitoring without the need for an external power supply. Two signal wires are all that are needed to obtain a linear, 0 to 5 V DC output voltage that may be easily interfaced with PLCs and DDC SCADA systems. The E-652V includes an on-board CT with a 14.5mm (0.570”) wire window that can accommodate up to AWG #2. The available input ranges are 0-10A, 0-25A and 0-50A. Multiple turns of the primary wire may be used to alter the input range. Where XX specifies the full scale input current (10, 25, 50 Amps AC) |

|

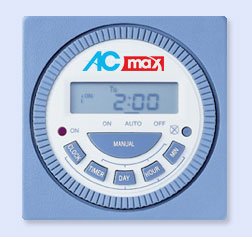

ETM-619

|

Electronic digital timer, programable (weekly & daily). |

PROGRAM SETTING:

|

|

ECM-102

|

|

ECM-203

|

|

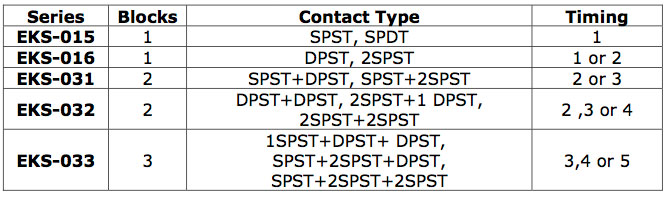

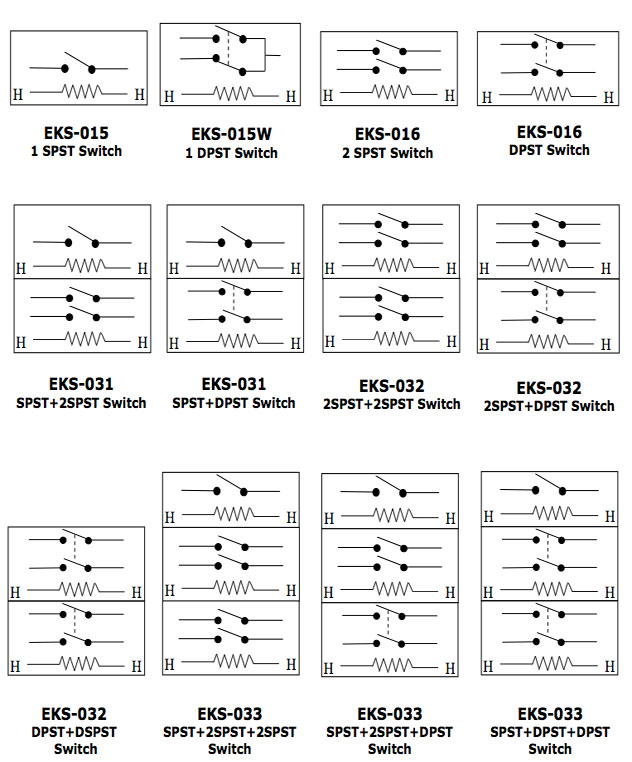

Series EKS Time Delay Relay (Sequencers)

|

Applications Furnace, Heaters, Heat Pump, and Air Conditioners |

|

|

EBT‐2

|

Digital Thermometer and Hygrometer |

|

|

|

ERC-30B-NE

|

Portable Data Recorder Simply Set Up And Record In Real Time With Remote Sensor Or Without & Use The Internal Sensor. Download To Your Computer Via The USB Cable Connection Analyze And Save Data. |

|

|

|

ERC-1+

|

Temperature Data Logger (Reusable Cartridge) |

|

|

|

ETPM-2024

|

Temperature Indicator C/F) |

|

|

|

ESD-1

|

|

SOLAR DIGITAL THERMOMETERS (C/F) |

|

|

|

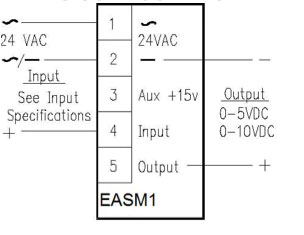

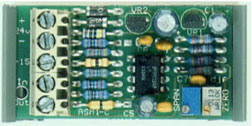

EASM1

|

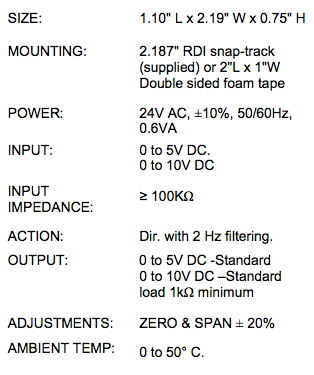

Analog scaling module |

|

The EASM1was designed as an analog signal scaling module to rescale control voltages or sensor signals to meet the input requirements of the various controllers. The EASM1 will also allow you to use existing sensors and scale the EASM1's output to match your controller’s input requirement. The EASM1's output can sink the controller’s input pull-up voltage on the application inputs. The EASM1 can be factory calibrated to your specific signal requirements. It can be snap - track mounted for panel use or be potted with detachable terminal block for field use. The EASM1 uses a half wave rectifier for 24V AC power input, with terminal 2 being common for the power supply, input common and output common. The input can be factory configured for voltage, current, or sensor signals either requiring a pull-up voltage or a load resistance. The signal then passes through two op-amp stages where it is scaled to the desired output signal.

|

|

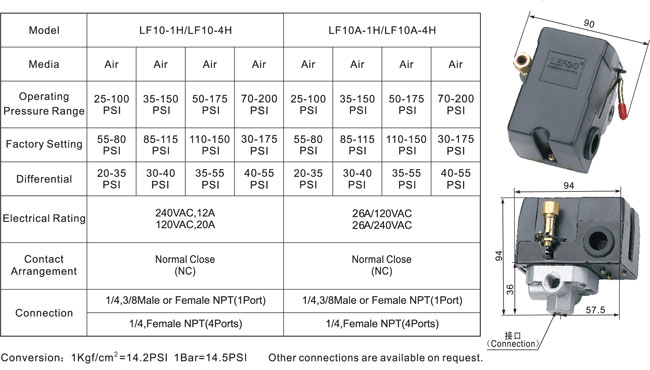

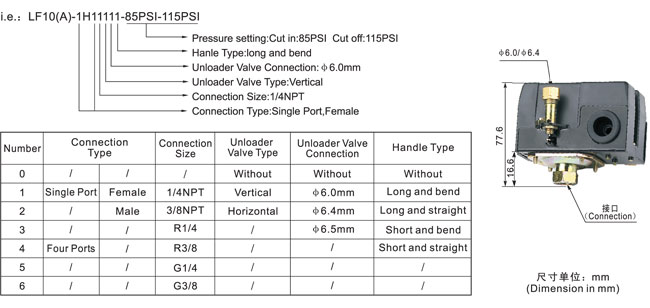

LF10 Pressure Switch

|

The LF10 pressure switches are used to regulate the tank pressure between two preset values on electrically driven air compressors. They are available with an unloader valve, which prevents compressors from starting under load, and an auto-off disconnect lever for manual cut off the compressor. A four port manifold style is available which provides a means for easy mounting of valves and gauges. |

|

|

|

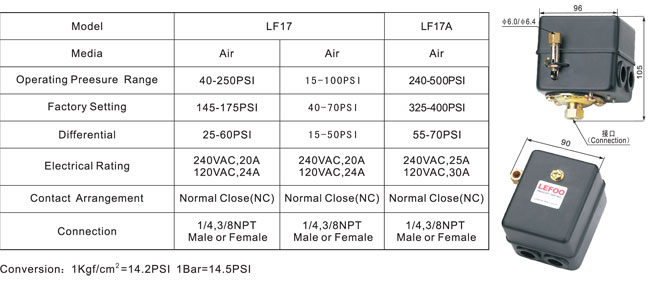

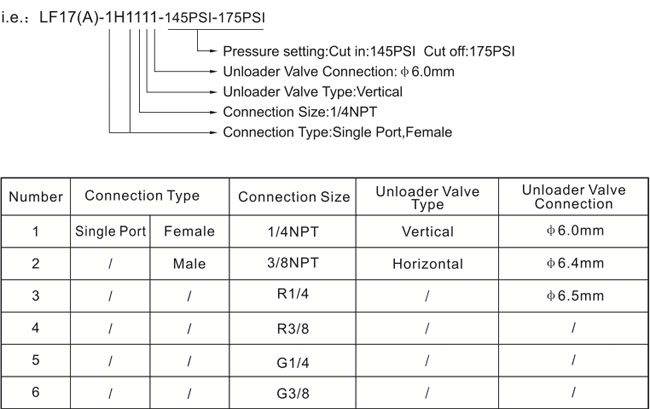

LF17 Pressure Switch

|

The rugged LF17 pressure switch is designed for the demanding requirements of larger, heavy duty commercial air compressors (up to 250psi). The sturdy painted steel case and cover resist the harsh conditions encounted in industrial applications. This style is available with an unloader valve to prevent the compressor from starting under load. |

|

|

|

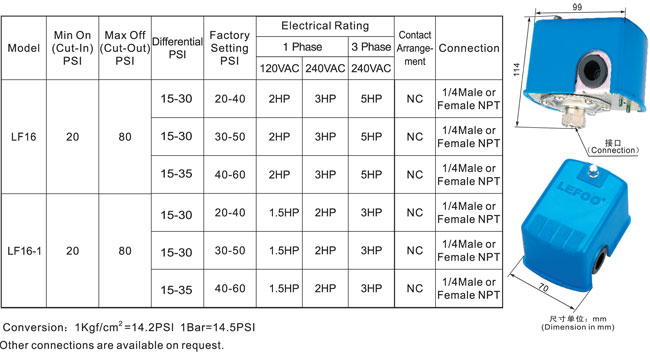

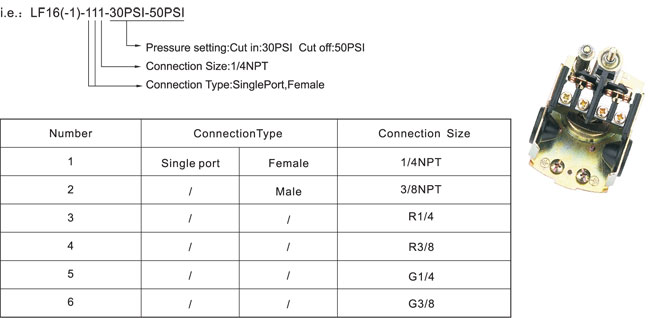

LF16 Water Pressure Switch

|

LF16 Water pressure switch provide time tested, reliable control for automatic water supply systems. The switch is universally acceptable for use as original equipment on water pumps or pumping systems. |

|

|

|

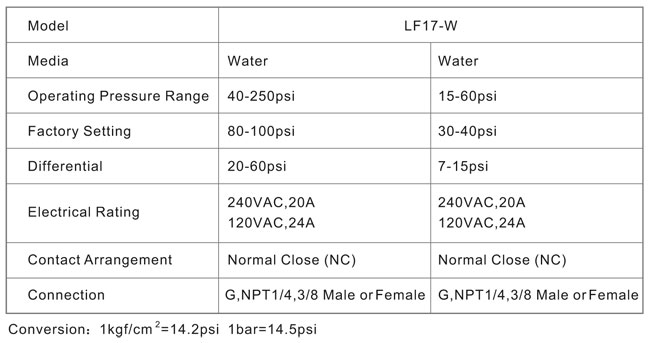

LF17-W Water Pressure Switch

|

The LF17-W is a ruggedized water pressure switch designed to meet the requirements of heavy duty industrial pumping applications. |

|

|

|

LF37 Diaphragm Pressure Switch

|

LF37 diaphragm pressure switch is available for various sumps, effluent, and sewage application to control the liquid level. Various switch settings are available for to turn-on or turn-off the pump. The diaphragm pressure sensing design make it more reliable than traditional float ball mechanism. |

|

|

|

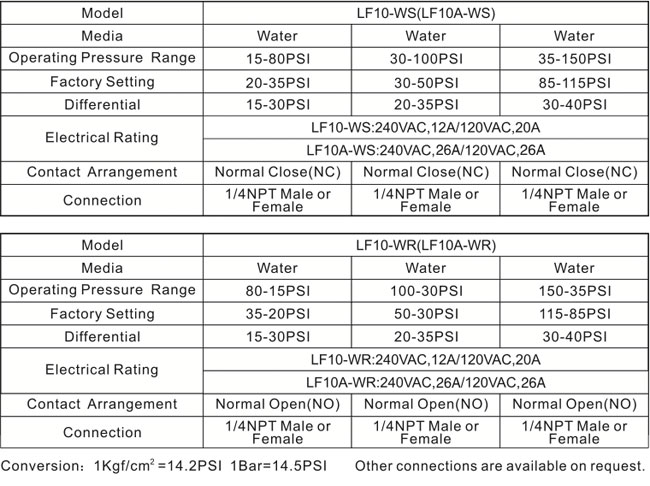

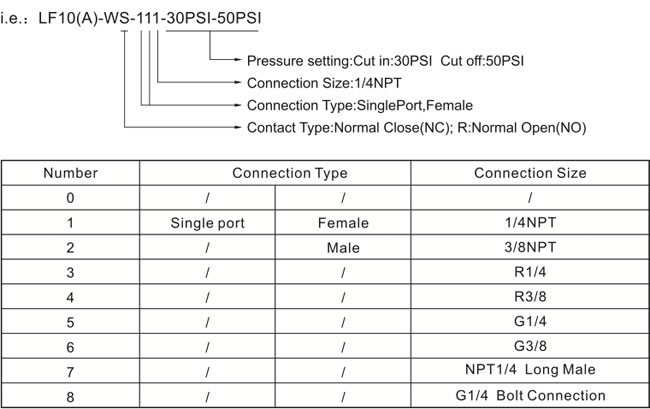

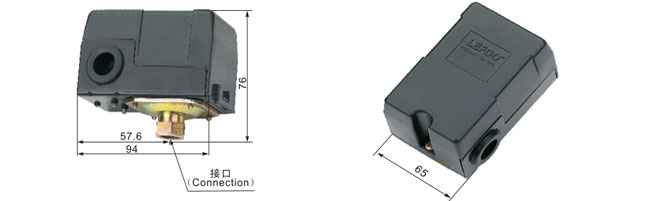

LF10-W Water Pressure Switch

|

LF10-W pressure switch provide time tested, reliable control for automatic water systems. The switch is universally acceptable for use as original equipment on water pumps or pumping systems. Lf10-WR can prevent thepump from starting whenever the system falls considerable below cut-in pressure. Upon the restorations of the water supply, it will automatically cut-in. A manual reset level is depressed until a build up of system pressure permits automatic operation. Its simple design makes it easy to use for professionals and nonprofessionals alike. |

|

|

|

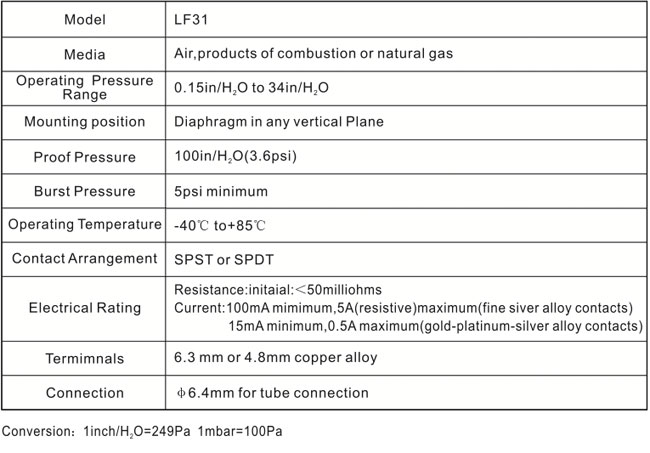

LF31 Pressure Switch

|

LF31 pressure switch was designed for use in the HVAC industry where safety and reliability ar essential. Despite the design intent this series has proven to be a viable solution for many pneumatic applications as well. Available in vacuum, differential and pressure models with fine silver or gold cross bar contacts, the LF31 is capable of detecting pressures as low as .05 inches of water. Factory calibrated units maintain set point tolerances of +/-10% over a temperature range of -40 F to 185 F due to its molded silicone diaphragm and the stability of its glass filled polyester body. LEFOO offers multiple electrical terminations and mounting options as well as bleed holes and 3 different size orifices. This switch series is not only the leading product in the market offering the highest quality and reliability but is also the most economical. |

|

|

|

LF32 Pressure Switch

|

LF32 switch is capable to sense tiny pressure change and widely used to control the flue of aerator, to monitor and fan and air conditioner; it is also for over heating protection and frost protection in industrial cooling system. Due to its outstanding design, the setpoint can been adjust visually. |

|

|

|

LF31 Pressure Switch (Vacuum Switch)

|

LF31 pressure switch was designed for use in the HVAC industry where safety and reliability ar essential. Despite the design intent this series has proven to be a viable solution for many pneumatic applications as well. Available in vacuum, differential and pressure models with fine silver or gold cross bar contacts, the LF31 is capable of detecting pressures as low as .05 inches of water. Factory calibrated units maintain set point tolerances of +/-10% over a temperature range of -40 F to 185 F due to its molded silicone diaphragm and the stability of its glass filled polyester body. LEFOO offers multiple electrical terminations and mounting options as well as bleed holes and 3 different size orifices. This switch series is not only the leading product in the market offering the highest quality and reliability but is also the most economical. |

|

|

|

LF32 Pressure Switch (Vacuum Switch)

|

LF32 switch is capable to sense tiny pressure change and widely used to control the flue of aerator, to monitor and fan and air conditioner; it is also for over heating protection and frost protection in industrial cooling system. Due to its outstanding design, the setpoint can been adjust visually. |

|

|

|

LF37 Diaphragm Pressure Switch (Water/Liquid Level Switch)

|

LF37 diaphragm pressure switch is available for various sumps, effluent, and sewage application to control the liquid level. Various switch settings are available for to turn-on or turn-off the pump. The diaphragm pressure sensing design make it more reliable than traditional float ball mechanism. |

|

|

|

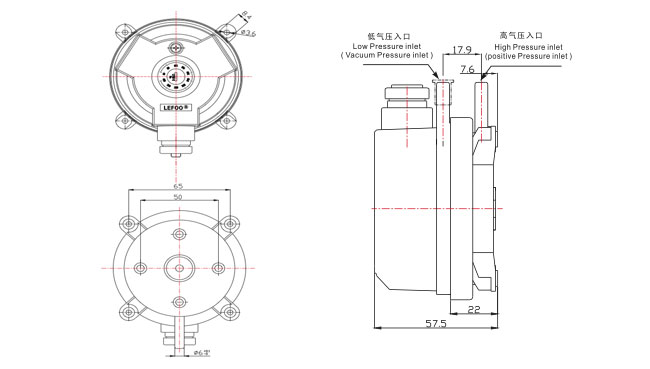

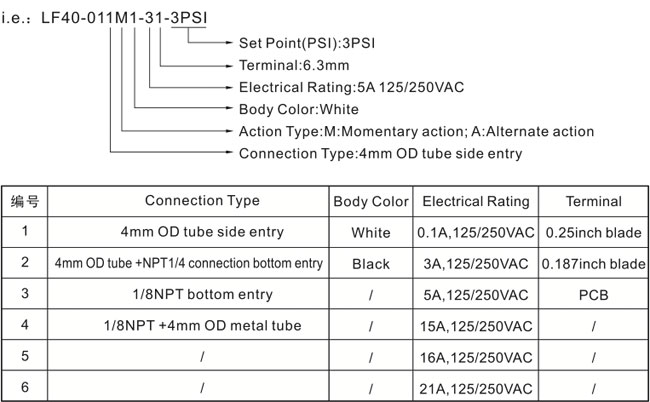

LF40-01 Air Actuated Switch

|

LF40-01 can be used togethr with an air button (also called as Actuator ) for remote control purpose. It is widely used in food waste disposers, pumps for swimming pools and spas, hot tubs, sanitary equipments, out door machines,medical equipments ect. As remote control switch, it i small enough to fix in the control box of the engine. Used as a remote control the air switch has two actions:

|

|

|

|

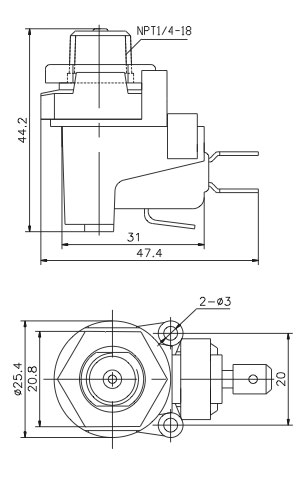

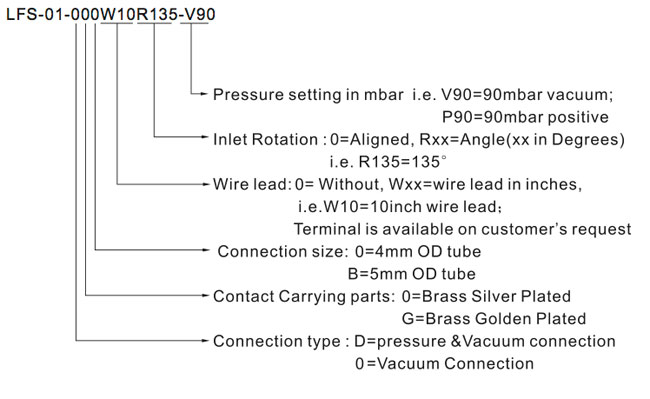

LFS-01 Pressure Switch

|

LFS-01 pressure switch is applied to detection of negative pressure, widely used in electrical appliance such as the vacuum cleaner, paking etc. It provides solder pin connections and is especially designed for mounting on "Printed Circuit boards". |

|

|

|

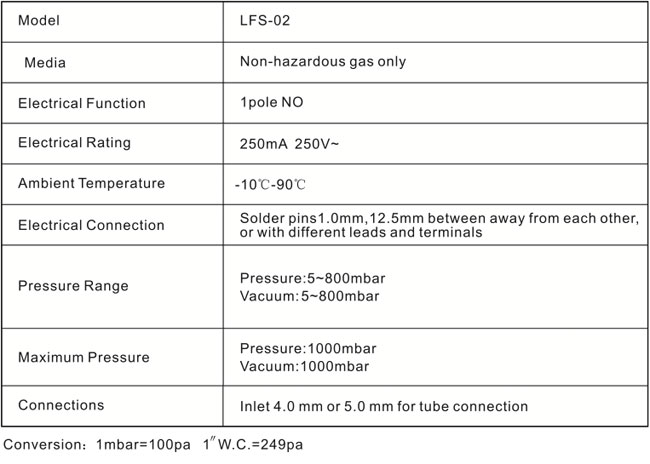

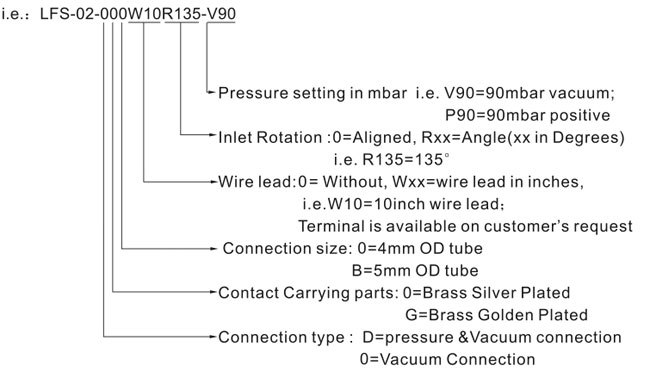

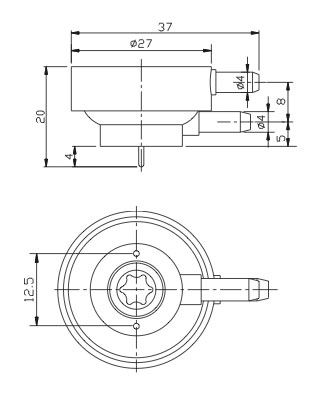

LFS-02 Pressure Switch

|

LFS-02 pressure switch is designed as an economical interface between pressure systems and Printed Circuit Boards. This switch can be used as a gauge or differential pressure switch with almost no hysteresis. Features of this switch include a body design that allows the pressure ports to be rotated, various terminal styles including wire leads. Strong and reliable, LFS-02 is a popular choice for many manufacturers. |

|

|

|