|

The ETCLO-830 Compressor Safety Controller has an anti-short cycle, solenoid valve time delay and lead-lag multi-settings. It is designed for use with any single and two-stage air conditioning and refrigeration equipment for compressor operation and protection control. If during normal operation any safeties are opened (low or high pressure switches), the compressor will shut off immediately. The controller then restarts the A/C unit again and a warning flag will be set. The compressor will be locked-out if safeties are opened for a second time. Manually opening and closing the thermostat can restart the A/C unit and reset the board. The fault can be attended to at any convenient time. The early warning feature will save the compressor from burnout. |

During normal operation of the compressor, contacts 5 and 6 will be energized, as well as the safety contacts that are in series with contact 6 and the compressor’s contactor. In this state, the warning flag (in the processor’s memory) will remain reset and normal operation will continue. If during normal operation safety contact(s) opens, the warning flag will be set and the compressor will shut off immediately. Terminals 5 and 6 will open for the duration of the selected anti-short cycle time delay (ASTD). Upon completion of this delay, contact 5, followed by 6, will re-energize. At this time there are two possible outcomes to this scenario: A - If the safety contact(s) is still open, the board will immediately go into lock-out mode, so that contacts 5 and 6 will be opened and the TRIAC output at terminal 4 (alarm output) will be activated. OR B - If the safety contact(s) is now closed, the compressor will start running again. However, the warning flag will remain set. If a safety contact(s) opens, the related compressor will immediately go into lock-out mode. Under condition B, the warning flag will be reset after 30 minutes of successful running of the compressor. In test mode, the 30 minutes for warning flag will be reduced to 4 seconds. When the thermostat is satisfied, the warning flag will be reset. The board is equipped with one green LED that indicates power to the board. Two red LEDs indicate the lock-out condition for each compressor. After power interruption, a unique time delay of 0–60 seconds for random start begins to avoid simultaneous start of multi-unit applications.

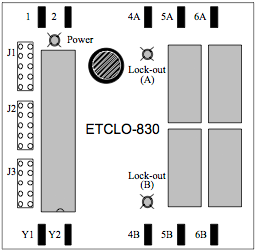

Terminal Designation

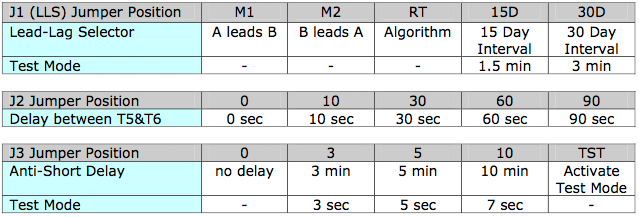

Jumper Settings Three sets of five position jumpers (J1, J2 & J3) are used to select functions as per tables below. Only one shunt should be applied to each jumper (except J3 in test mode).

The ETCLO-830 is designed for class 2 circuits and should be powered by an UL recognized class 2 24 VAC transformer. |

|